Shri B. P. PATI* & Shri SUNIL BHAWARIA**

Coal/Lignite PSUs have spearheaded commendable efforts in leveraging mine water to alleviate water scarcity, aligning with the Jal Shakti Abhiyan for water conservation initiated by the Government of India.

Introduction:

At the heart of India’s energy scenario, coal is positioned to continue serving as the cornerstone of the nation’s energy supply. Major players in the coal and lignite sector, including Coal India Limited (CIL), NLC India Limited (NLCIL), and Singareni Collieries Company Limited (SCCL), play a crucial role in driving coal production in India to meet increasing energy demand. These entities have set ambitious targets to boost coal production in the upcoming years. It is pleasing that these companies are very much responsive to their environmental sensitivities. Going beyond a singular focus on coal output, concerted efforts are being made to improve the social and environmental conditions in coal mining regions. Various sustainable and environment friendly measures are being adopted towards this end. Among these measures, the strategic utilization of mine water emerges as a pivotal approach, contributing significantly to the broader agenda of fostering social and environmental well-being in coal mining areas.

With the world’s population soaring and rapid urbanization and industrialization on the rise, the pressure on available water resources has reached unprecedented levels. It is projected that by 2030, the world could face a 40% global water deficit if current trends continue. India, too, grapples with acute water stress, with per capita water availability dwindling at an alarming rate. To address this crisis, it is imperative to tap every possible resource of potable water.

Mine Water Utilization – A Sustainable Approach:

One promising avenue for water harnessing is the efficient utilization of mine water. In coal mining, large volumes of mine water accumulate in sumps, presenting an opportunity for gainful utilization. Coal/Lignite PSUs have spearheaded commendable efforts in leveraging mine water to alleviate water scarcity, aligning with the Jal Shakti Abhiyan for water conservation initiated by the Government of India.

Sources of Mine Water and its Utilization:

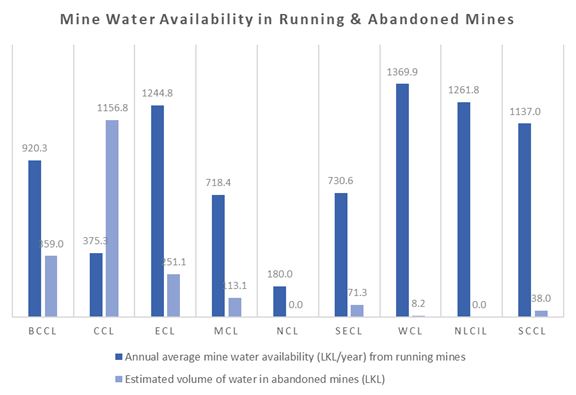

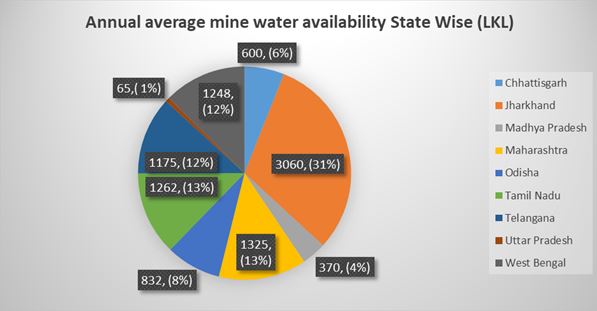

In the coal mining process, aquifers surrounding coal seams are exposed, leading to the accumulation of groundwater in mine sumps. To ensure the safety of mining operations, the gathered mine water is pumped to a separate surface sump. Additionally, the mined-out voids serve as reservoirs for strata seepage water and runoff from surrounding catchment areas, functioning as extensive water harvesting structures. According to the Status Report on Mine Water Utilization (2021) compiled by CMPDI, the yearly mine water available in 347 operational and 94 abandoned mine voids of Coal/Lignite PSUs amounts to approximately 1000 million cubic meters.

Monitoring and Treatment of Mine Water:

Mine water accumulation arises primarily from cutting aquifers in underground (UG) mines and cutting aquifers, along with rainwater runoff, in open-cast (OC) mines. Fortunately, the general quality of mine water in coal mines is suitable for domestic and irrigation purposes with minor treatment, such as sedimentation, filtration, and disinfection. Acid Mine Drainage is rare, and occurrences of trace elements or heavy metals beyond permissible limits are infrequent.

To ensure the quality of mine water, regular monitoring is conducted, focusing on parameters such as pH, Total Suspended Solids (TSS), Total Dissolved Solids (TDS), Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD), and Oil & Grease. Coal companies adhere to the Central Pollution Control Board’s (CPCB) standards, monitoring all 33 prescribed water quality parameters annually.

Diverse Applications of Mine Water:

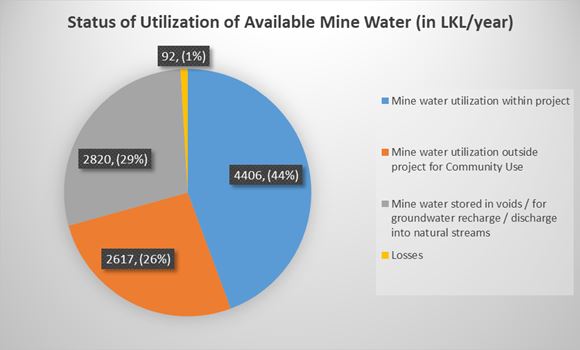

This collected mine water is typically devoid of pollutants and is utilized for various community purposes. Mine water, after passing through settling tanks, finds diverse applications:

- Industrial use for dust suppression, plantation, firefighting, machinery washing, and sprinkling in UG workings.

- Domestic use in colonies and offices of coal projects after appropriate treatment.

- Community supply for domestic and irrigation purposes, both departmentally and through Memorandum of Understanding (MoU) routes with State Governments.

- Supply to other industries and municipal corporations.

- Creation of recreational areas, fish farming, and groundwater recharge.

- Water filled abandoned mine voids function as a water source for plant life, animals including wildlife.

Status of Mine Water Utilization:

Under the guidance of Ministry of Coal, volume of mine water supplied for community purposes has been around 16,012 LKL thereby benefitting annually more than 17.7 lakh people in 981 villages of 9 coal bearing states during FY 2018-19 to FY 2022-23. Volume of mine water supplied for irrigation purpose has been 10762 LKL & for domestic/ drinking purposes has been 5250 LKL.

Further, Coal/Lignite PSUs have entered into Memorandums of Understanding (MoUs) with their respective State Governments to provide mine water for community purposes. As per the MoUs, Mine Management is entrusted with delivering raw mine water to surface reservoirs, while the State Government takes on the responsibilities of filtration, operation, quality control, and distribution. The MoUs encompass both operational and abandoned mine voids, with identification of such sites and the formulation of Mine Water Utilization Schemes being carried out collaboratively by State agencies and coal companies. Examples of such collaborations include:

- An MoU between the Jharkhand Government and CIL focusing on utilizing mine water for villages in the command area of CCL, BCCL, and ECL.

- An MoU between the West Bengal Government and ECL aimed at using mine water for community irrigation.

- An MoU between WCL and MAHAGENCO designed to provide mine water to MAHAGENCO power plants near WCL mines.

- An MoU between WCL and Vidarbha Irrigation Development Corporation facilitating the supply of surplus mine water from WCL mines to VIDC.

- An MoU between the Chhattisgarh Government and SECL for the supply of mine water to PHED, Water Resource Department, and other government agencies.

- NLCIL supplying mine water to the Chennai Metro Water Supply Scheme by transporting mine water from Veeranam lake to Chennai.

- In SCCL, excess mine water is discharged into nearby tanks for community use, including drinking and irrigation purposes.

As part of gainful utilization of Mine Water, the water-filled voids within the mines offer promising prospects for fish farming and water tourism, in addition to serving the needs of the local community. South Eastern Coalfields Ltd. has successfully repurposed its disused Quarry No. 6 at the Bishrampur opencast mine into a center for pisciculture and water sports. Located in Kenapara, approximately 350 km north of Raipur, the site features 32 cages dedicated to pisciculture and fish farming, along with amenities like a floating restaurant and boating facilities. Self-help groups have been established to oversee the pisciculture activities, providing a sustainable livelihood for the local tribal population. This initiative stands as an environmentally friendly and economically viable means of income generation for the communities, yielding an annual fish harvest of around 800 quintals.

A reverse osmosis (RO) filter plant has been constructed inside the premises of Ningah Colliery, Sripur Area in ECL. The filter plant has a capacity of 5000 litres/hour. The treated water is used for drinking purpose as well as for other domestic purpose.

WCL’s Coal NEER project is a significant initiative aimed at treating and bottling mine water from the Patansaongi UG mine in Nagpur District, Maharashtra. Aligned with the Jal Shakti Abhiyan for water conservation, the project treats accumulated mine water through sedimentation, slow sand filtration, RO processing, and UV treatment. The RO plant, operational since 2019 with a 10,000 LPH capacity, holds certifications for packaged drinking water. Branded as “COAL NEER,” the water is sold commercially in WCL’s jurisdiction and government offices. Priced at Rs 7/- per 500ml bottle and Rs 10/- per 01-litre bottle, profits support community service initiatives, providing pure drinking water to nearby villages. Collaborating with Self-Help Groups, WCL distributes water directly to villagers, benefiting areas like Patansaongi, Belori, Tadulwani, Babulkheda, Kavdas, Itangoti, Champa, Kusumbi, Sillori, Bramhapuri, Khangaon, Khodadongri, Veltur, and Beendala, impacting an estimated 1 lakh people.

Conclusion:

Mine water utilization emerges as a beacon of hope in the face of impending water crises. The successful implementation of projects by Coal/Lignite PSUs not only addresses water scarcity but also sets a precedent for responsible water management. Every drop matter, and through innovative initiatives, the coal sector is contributing significantly to water conservation and sustainable development.

The Coal Sector’s commitment to the meaningful utilization of mine water is in accordance with the National Water Mission and aligns with the Jal Shakti Abhiyan – Catch the Rain-2023 campaign, specifically focusing on “Source Sustainability for Drinking Water,” launched by the Ministry of Jal Shakti.

*Joint Secretary, Ministry of Coal, GoI &

** Manager, Coal India Limited

About Author:

Shri Bhabani Prasad Pati, Indian Forest Service Officer from Gujarat Cadre (1994 Batch), has obtained M.Sc. in Botany from Utkal University & Post Graduate Diploma in Environment Management from CIPSEM, TUD, Germany. He has 29 years of experience at the Centre and State Levels.

Prior to rendering services in Ministry of Coal, he worked in different capacities in the Government of Gujarat such as Chief Conservator of Forest (V&P) & has also functioned as CGM in GMDC. He has also worked as Government Nominee Director in BCCL & WCL and is presently in SECL.

He is rendering his services in the Ministry of Coal as Joint Secretary since 2018. He played an instrumental role in establishing a well functioning Sustainability & Just Transition Division in the Ministry of Coal which advise, mentor, plan & monitor the sustainability, climate change & Just Transition aspects in the Coal Sector for maximizing resource utilization in a sustainable way.